Team

STARFLEET COMMAND

SSC 2020 Grand Prize Winner

OUR SOLUTION

How Does it Work ?

Our Solution, is designed from the ground up to achieve a cost of < $20,000 USD per debris cleared in a reusable configuration. The solution involves primarily 2 spacecrafts , the interceptor and the fuel tanker. The interceptor employs a unique Sling de-orbit method to de-orbit small debris. Once interceptor depletes its propellant tank, it heads back to the fuel tanker to refuel and proceed to a new set of missions.

Our Solution Primarily focus on hard to track small debris (~10cm or smaller) , more than a Million pieces in Low earth orbit. These debris pose a huge danger to both Human and hardware in space. However our solution could also deal with larger debris .

Animation Made In-house with Blender 2.81a

Meet the Interceptor

The interceptor, the workhorse of our system. The interceptor is designed from ground up to perform the mission of active debris removal. In order for a breakthrough in efficiency, cost and reusability.

We leverage several innovative design choices from the start that has never been done before. These 3 primary design choices are Green propellant, Micro turbo-machinery electric fuel system and a sling de-orbit method.

The Sling-Shot De-orbit

The Sling-Shot, is designed as a method to impart kinetic energy into a target debris without the need to use propellant.

Several mechanisms are considered to achieve this including electromagnetic accelerator (Rail Gun), however most of the solution are ether too mechanically complex , requiring too much power or it has a undesired "recoil" that needs to be compensated by propellant.

Our Interceptors each features a 2x 15 meter boom rotating on the same axis and spins up to 150 rpm before releasing both debris in short successions to prevent unbalance.

Key Benefit of Sling-Shot :

Low Mechanical Complexity

(2x Deploy-able booms and electric motors)

Strong & Light Weight Construction.

MR60H Carbon Fiber Composite Deploy-able Boom

Zero Fuel Required for de-orbit. Only low Electrical power for the sling geared electric motor.

No Undesired "Recoil/kickback"

Low Cost Per De-Orbit

( $ < 25,000 per de-orbit)

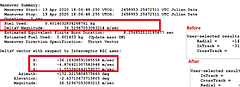

Advanced true to life Mission Design using STK

The Mission Design is the backbone of mission success and cost optimization. Our team utilize real TLE data and an in-house developed TLE decoder and data visualization dashboard to choose debris and string them into optimized missions.

Data from TLE is fed into STK (System Toolkit) with full set of Keplerian Parameters (Apogee , perigee, Inclination, Eccentricity , RAAN , AOP). STK simulations are done without assumptions. Parameters taken into account are the fundamental Keplerian Parameters, non-spherical gravitational source of earth , perturbations from various sources such as moon, sun and Jupiter.

Power BI TLE (4LE) Visualization

Detailed Burn Maneuvers Using STK

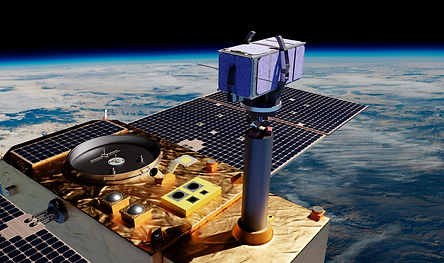

Meet the Fuel Tanker

The Fuel Tanker, a key part of our solution. The main purpose of the fuel tanker is to take advantage the economics of scale, transport large quantities of propellant to space using existing rockets at once , leading to much lower cost per unit mass .

Once depleted, the interceptor simply docks to the fuel tanker with the help is standard 18 inch international docking ring and a robotic arm , refuels and proceed to next mission.

The entire fuel station rotates at a slow 1 revolution per 2 mins to for positive propellant expulsion.

Interceptor

Pods

Fuel Tanker

Pods

The PODs, are small propulsive pods docked with the Fuel tanker at launch . These pods can be transfered by the interceptor to a large satellite. PODs can grip onto satellite docking adapters.

Pods can be used once off to deorbit multi Ton satellites

Find Out More

Team Star-Fleet Command Technical Report

Shanmugam Surya

(Mission Designer)

Gallery

.jpg)